IR HEATER UV LAMP

UV (ultraviolet rays) lamp

We can make proposals to meet customers' needs in many fields such as environment, medical, food, liquid crystal, semiconductor, etc.

Various types of UV lamps are indispensable for various processes.

-

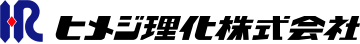

Ultra high pressure mercury lamp

Used as exposure lamps in LCD panel, PDP, and printed circuit board manufacturing processes.

-

Mercury xenon lamp

Compared to super high-pressure UV lamps, these lamps are used for curing resins, ink impressions, etc., and are characterized by a higher ratio of radiation at wavelengths below 40 mm.

-

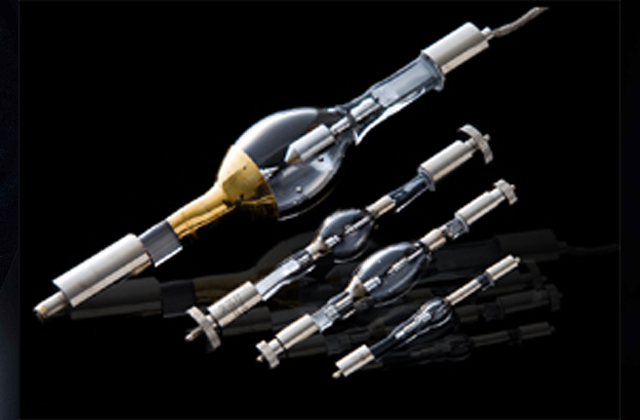

Xenon lamp

The light spectrum in the visible light range is continuous with good color rendering and high luminance like sunlight. Color variations and changes are extremely small, and a large amount of light can be obtained in a short period of time.

-

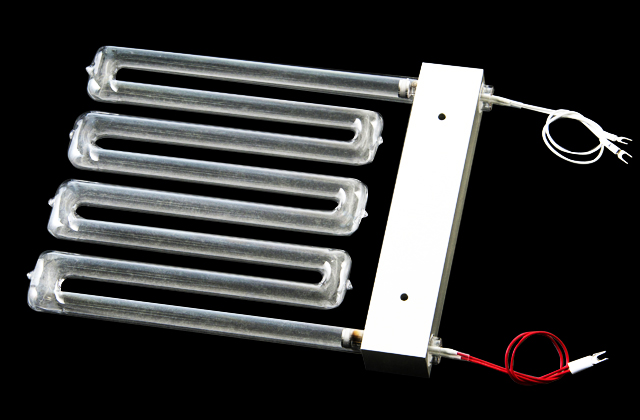

Low pressure mercury lamp

It is used in various fields such as water sterilization, air sterilization, dry washing, LCD panel manufacturing for surface improvement, and in food factories, pharmaceutical plants, and sewage systems for sterilization applications.

-

High pressure mercury lamp

This lamp is used for surface modification, curing and drying of clear coating materials, and can be used to cure a wide range of areas.

-

Metal halide lamp

By adding halides, a wider range of longer wavelengths can be generated, which is used for curing inks, pigmented coatings, adhesives with thick films, and laminating glass.